| No. | | |

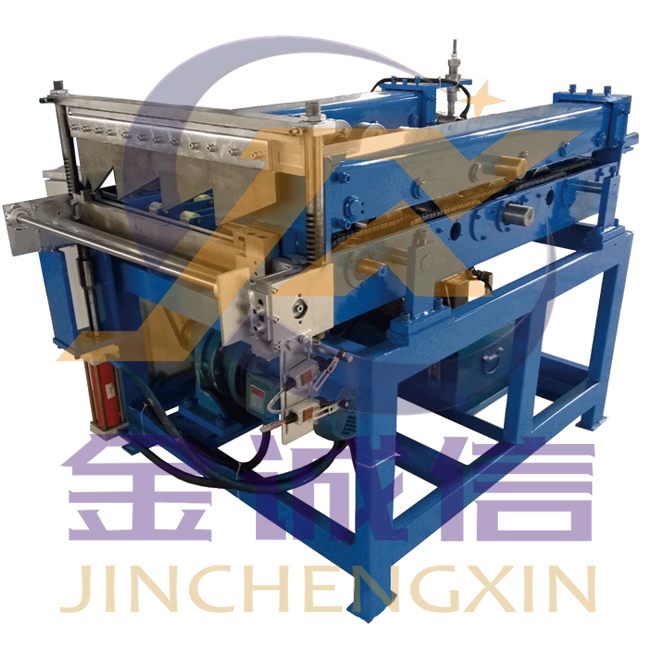

| 1 | Material of the profile | GI or color steel |

| 2 | Thickness range | 0.3-0.8mm |

| 3 | Main motor power | 4kw |

| 4 | Electric Voltage | 380V, 50Hz, 3Phase |

| 5 | Roll station | 8 stations |

| 6 | Roller material | ASTM1045 chrome plated surface with chrome, CNC machiening |

| 7 | Shaft diameter | ¢70mm material: SAE1045 with quenching and tempering |

| 8 | roll forming speed | not less than 15m/min |

| 9 | Transmission | by chain, one inch, single line |

| 10 | Others | Roll former has leveling bolts in the base for adjusting the

leveling |

| Machine base frame adopt H beam welding steel |

| In the main roll forming machine have 2 buttons for urgency stop if

happen any malfunction. |

| Machine adopt new station to make machine more strong |

| To avoid a |

5. Service

· 5 engineers with more than 20 years experience

· 30 professional technician

· 22 sets advanced CNC production lines on site

· 3 years maintenance and whole life technical support

· Free accessories can be offered to you during the warranty period

6. Quality assurance

The company organizes the production as per ISO9001:2008 standard.

From design control, process control, inspection control to

delivery, installed and service, we all operating a whole strict

process control system. The running of the quality system performs

quality manual, procedure files, work instruction and related

technical and management standard together with standard and

regulation layout by the company. Quality system realizes whole

screw and whole procedure control completely.

Quality assurance procedure for important out-source parts.

a. Mainly out-sourced parts: control system, cylinder, hydraulic

components, motor, pump etc.

b. After evaluation, select qualified suppliers as business

partners.

c. Purchasing according to plan, purchase contract, quality

requirement, technical standard, and inspection standard.

7.Delivery and package

7.FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and

Control system. As the new buyer, please kindly know that price not

the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as

detailed request, because raw material , size , production usage,

machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to

Door and so on. Please kindly tell the detailed port name for

competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed

ISO9001:2000, CE,TUV/BV(.) Certificate.

Q5. How about the after-sale service?

A5: We provide 15 months free warranty and free technical support

for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q6. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!

8.Our service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you

install and debug the machines well. Buyer should pay $60 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period

of 18 months starting from delivery. Because of the quality of

equipment during guarantee period, we will provide the parts free

of charges, which is in the conditions of correct operation.

(Natural disasters or factors which can’t forced by human are

excluded).

C. Training

During installation and adjustment of the equipment, our engineers

shall provide the training to

buyer’s personnel request to operate and maintain the equipment.

Including foundation construction, electrical works, hydraulic oil,

safe operation and non-standard safety items, testing material and

etc.

D. Lifetime services

Life time services to every customer.

.