Botou Golden Integrity Roll Forming Machine Factory is located in "the town of casting molds", enjoying convenient and

highly effective transportation for being close to Tianjin Port,

No.104 National Way, No.106 National Way and Jingjiu Railway.

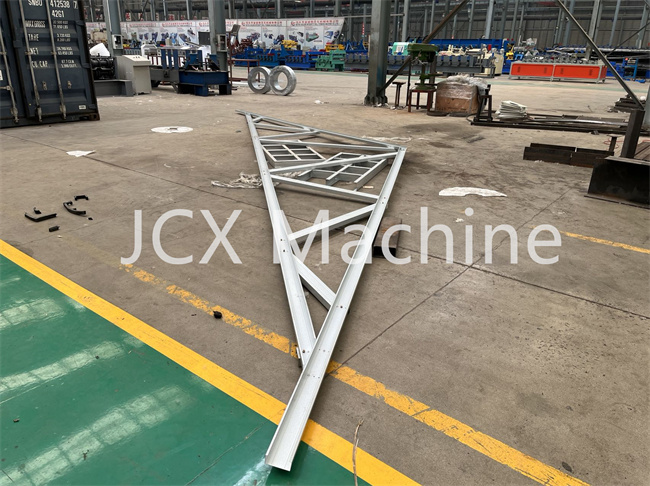

Our technical force is abundant. Production equipment is advanced,

detection means is complete. We specialize in the professional

production of various types of roll forming machines, and the

development and production of fully automatic intelligent control

roll forming machines of C-shaped steel and dust collector anode

plates, and other equipment.

On the basis of traditional roll forming machines, we also develop

new computer fully automatic roll forming machines, roof and wall

panel forming machines, glazed tile forming machines, floor bearing

plate forming machines, high-speed barrier devices, double color

steel tile molding machines, C and Z steel machines, arch

appliances, sandwich composite plate machines, shearing machines,

bending machines, and heat insulation sandwich composite machines.

Our products have reached the advanced level in the same industry.

As beautiful appearance, reasonable structure, and tile-based

standards of our products, they are popular among new and old

customers. Products are sold to domestic enterprises.

Our factory has highly qualified and experienced professionals and

highly skilled construction workers to serve you. Our factory can

design and produce various kinds of special-shaped cold-formed

molding equipment for different needs of the users.

You are welcome to contact us for more information.

BOTOU Golden Integrity roll forming

machine

BoTou Golden Integrity Roll Forming Machine Factory is located in

"the town of casting molds", Our factory has highly qualified and experienced professionals and

highly skilled construction workers to serve you.You are welcome to contact us for more information.